Air-Cooled vs. Water-Cooled Laser Cleaners: Which Is Right for You?

Share

When choosing a laser cleaning machine for your business, one of the most important decisions is whether to go with an air-cooled or water-cooled model. Both types of systems offer unique advantages, but understanding their differences can help you select the best option for your specific needs. In this blog, we’ll compare air-cooled and water-cooled laser cleaners, exploring the key factors to consider when making your choice.

1. Cooling System Design: The Heart of the Difference

The most obvious distinction between air-cooled and water-cooled laser cleaners lies in their cooling mechanisms.

-

Air-Cooled Laser Cleaners use ambient air to cool the system. The machine’s internal components are kept cool by fans that circulate air around the system, preventing overheating.

-

Water-Cooled Laser Cleaners, on the other hand, rely on a closed-loop system of water circulation. This typically involves a water pump, cooling tower, and pipes that absorb and remove heat from the system.

2. Portability and Size

One of the primary advantages of air-cooled laser cleaners is their portability. Since they don’t require water pumps, pipes, or external cooling tanks, air-cooled models are compact and lightweight, making them ideal for on-site applications or jobs that require flexibility and mobility. You can easily transport them to different locations without worrying about additional equipment.

In contrast, water-cooled laser cleaners are bulkier due to the need for a cooling system. The additional components can make them less portable, meaning they are typically better suited for larger operations with a stationary setup.

3. Maintenance Requirements

The maintenance of both air-cooled and water-cooled systems varies significantly.

-

Air-Cooled Laser Cleaners are generally easier to maintain because they don’t have complex water circulation systems that could develop issues like leaks or contamination. Without water pipes, there’s less risk of rust or scaling, and fewer components to clean or replace.

-

Water-Cooled Laser Cleaners, however, require more upkeep. You need to maintain the cooling system, ensure there’s no leakage, and clean or replace water filters periodically. If the water quality isn’t properly maintained, it can cause corrosion and damage to internal components.

4. Efficiency and Cooling Power

Water is a more efficient heat conductor than air, so water-cooled laser cleaners can provide more consistent cooling, making them ideal for heavy-duty applications where extended use is required. They are designed to handle higher heat loads and are often preferred for long-duration tasks.

In contrast, air-cooled laser cleaners are typically sufficient for lighter tasks or short to medium-duration cleaning jobs. While they are effective for most standard industrial applications, they may not be the best choice for extended use in high-temperature environments.

5. Environmental Impact

Both air-cooled and water-cooled systems are more eco-friendly than traditional methods like sandblasting or chemical cleaning. However, air-cooled laser cleaners have an edge in sustainability because they don’t consume or waste water. This makes them a great option for companies focused on reducing their environmental footprint.

Water-cooled systems, while still more environmentally friendly than traditional cleaning methods, do require ongoing water consumption. Depending on the operation’s scale, this could lead to higher water usage, making air-cooled systems a more sustainable option in the long run.

6. Cost Considerations

Air-cooled laser cleaners tend to have a lower initial purchase cost because they don’t require additional components like water pumps and cooling systems. Additionally, their maintenance costs are typically lower since they don’t require as much upkeep.

Water-cooled laser cleaners, while offering superior cooling for demanding applications, can have higher operational costs. The need for a more complex cooling system means more maintenance, and potential water-related expenses (like water treatment or replacement) could add up over time.

7. Applications

Both types of laser cleaners can be used across various industries, but certain applications are better suited for each system.

-

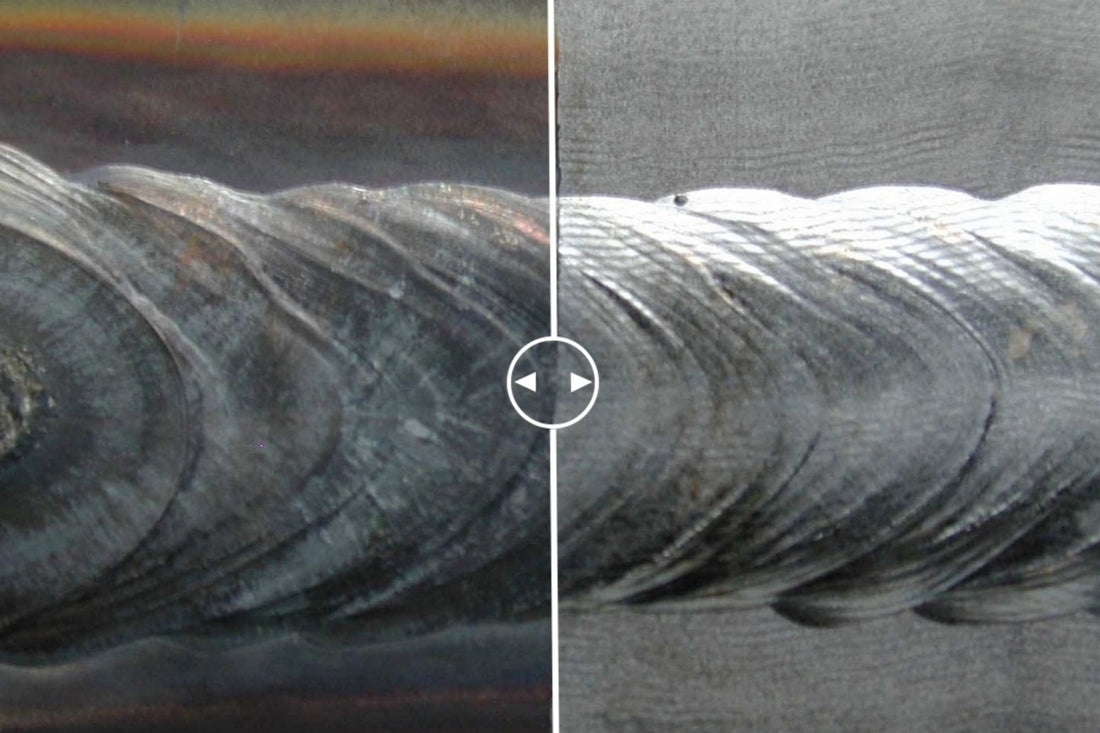

Air-Cooled Laser Cleaners are ideal for industries that require flexibility, portability, and lower maintenance, such as automotive restoration, small-scale manufacturing, and general surface cleaning. They are also effective for light to medium-duty tasks like paint removal, rust cleaning, and surface preparation.

-

Water-Cooled Laser Cleaners are better suited for industries that require long-term, high-performance cleaning, such as heavy-duty industrial manufacturing, aerospace, and large-scale restoration projects. These machines can handle the heat generated during extended cleaning sessions, making them suitable for demanding applications.

Conclusion: Which One is Right for You?

The decision between air-cooled and water-cooled laser cleaners ultimately depends on your specific needs.

-

If you’re looking for a portable, eco-friendly, and low-maintenance solution for light to medium-duty applications, an air-cooled laser cleaner is likely the best fit.

-

If your business requires a heavy-duty, high-efficiency cooling system for longer cleaning sessions or larger operations, a water-cooled laser cleaner may be the better option.

At SFX Laser, we offer a range of both air-cooled and water-cooled laser cleaners to suit various industries and applications. Contact us to discuss which model will best fit your needs, and let us help you find the right solution for your business!