1

/

of

13

SFX 200W Spot Laser Welder Welding Machine Upgrade CCD Function Metal Gold Silver Jewelry Repair Tool 220V

SFX 200W Spot Laser Welder Welding Machine Upgrade CCD Function Metal Gold Silver Jewelry Repair Tool 220V

Regular price

$6,999.00 USD

Regular price

Sale price

$6,999.00 USD

Unit price

/

per

Import Duties Included. Discounts Calculated at Checkout.

Couldn't load pickup availability

Shipping and Delivery

Shipping and Delivery

- After-Sale Centers in US, Canada, Europe

Our global after-sale support centers ensure prompt and localized assistance for any post-purchase inquiries or issues, providing a convenient and efficient solution. - Remote Assistance for Operational Concerns

Experience hassle-free operation with our remote assistance services, addressing any operational issues you may encounter. Our support team is readily available to guide you through troubleshooting steps. - Lifetime Online Technical Support

Enjoy continuous technical support for the entire lifespan of your product. Our online support ensures that you have access to expert guidance whenever you need assistance, ensuring long-term satisfaction. - Efficient Door-to-Door Free Shipping

Benefit from our free and expedited shipping services directly to your door via reputable carriers such as DHL, UPS, or FedEx. Expect delivery within 7-10 days, ensuring a swift and reliable shipping experience. - No Import Duty

As part of our commitment to customer satisfaction, most customers can enjoy a seamless purchasing experience without the burden of import duties, making the entire process cost-effective and transparent.

Warranty

Warranty

1 years warranty for the laser source and the whole machine.

Note:

- From the date of purchasing this product, our company provides free warranty within one year. lf the machine need to be returned tothe factory for repair, the user only needs to bear the cost of two-way transportation.

- This product is repaired free of charge for life, and the user only needs to bear the cost of spare parts and two-way transportation.

PARAMETERS

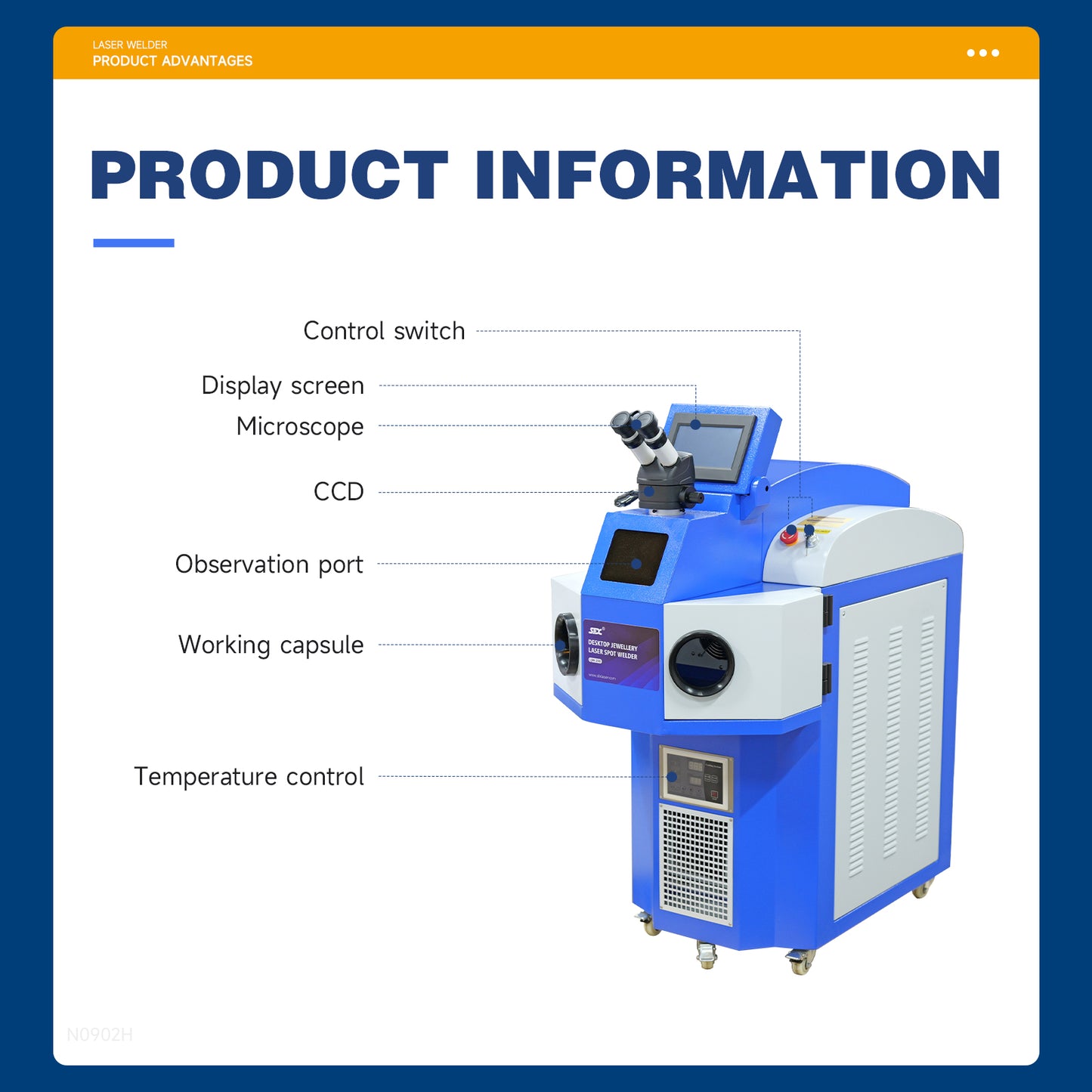

- Model: LJW-200

- Laser Wavelength: 1064nm

- Laser Frequency: 0-50Hz

- Condenser Reflector: Imported Ceramic Condensing Cavity

- Maximum Laser Power: 200W

- Energy: 60J

- Voltage: 220V 1 Phase / 380V 3 Phase (Voltage transformer required for 110V)

- Pulse Width: 0-20ms

- Spot Adjustment Range: 0.3-2.5mm

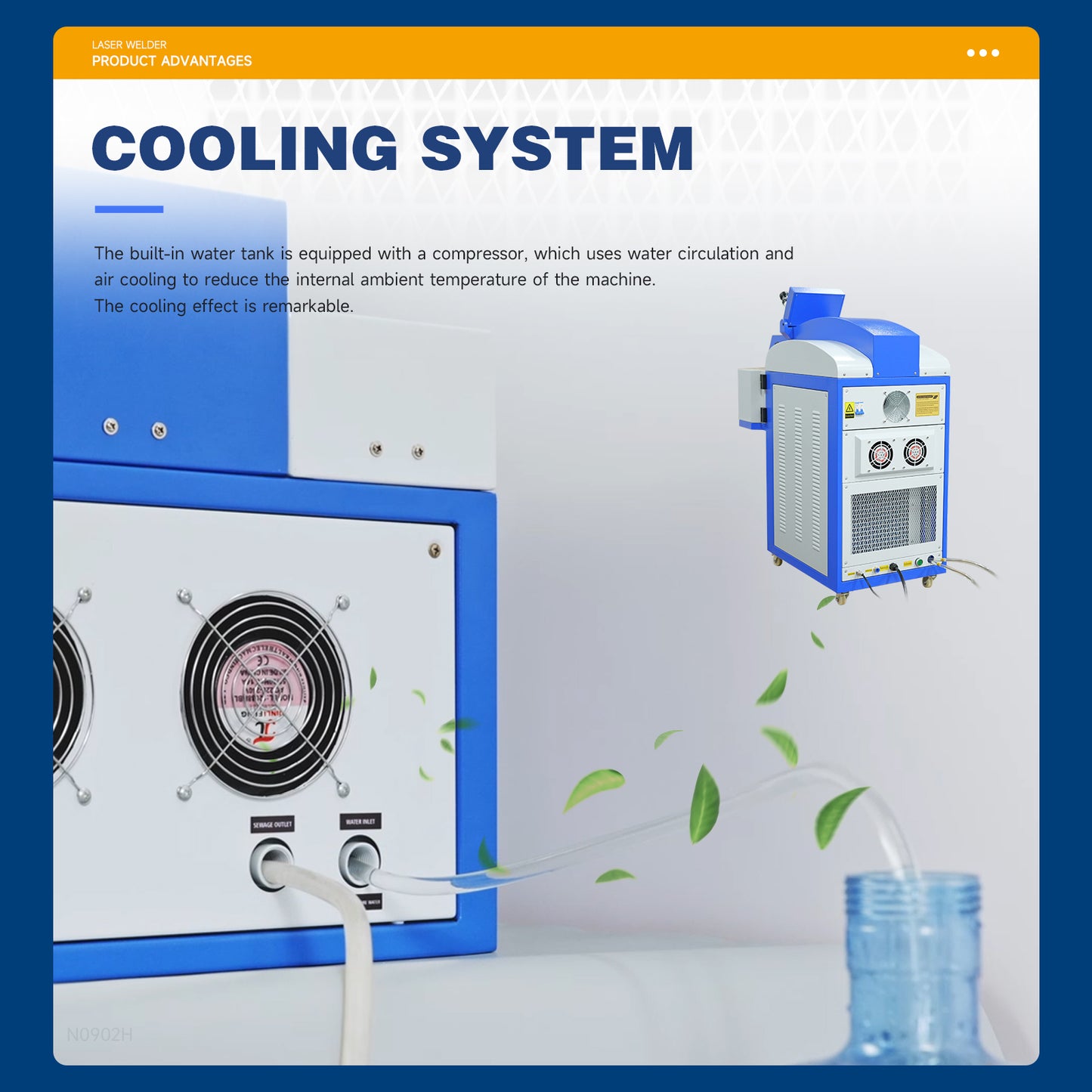

- Cooling System: Built-in Water Cooler 1P

- Rated Power: 6.5KW

- Packaging Size: 11007001300mm

- Gross Weight: 180kg

- Usage Environment: 10-30°C

PRODUCTS ADVANTAGES

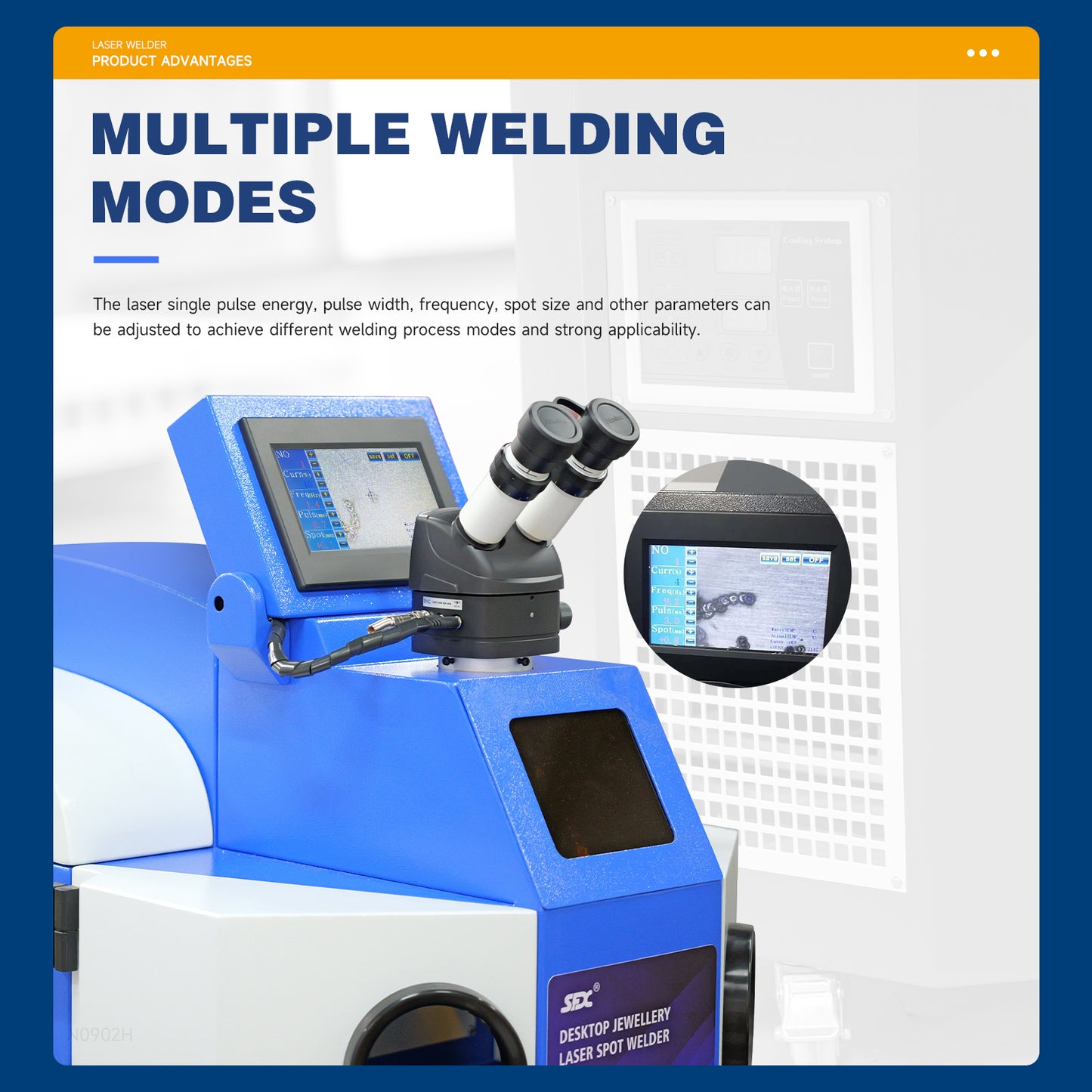

- High Precision: The jewelry laser welder offers precise control with a 0.3-2.5mm spot size. The energy, pulse width, frequency, and light spot size are highly adjustable, allowing for different welding effects based on specific needs.

- Microscope Observation System: Equipped with a specialized microscope observation system with crosshairs, along with a high-speed electronic filter device, it ensures the protection of the operator's eyes during the welding process.

- Advanced Digital Control: Featuring a capacitive touch screen, the digital control system provides a more responsive and user-friendly interface compared to traditional screens. The visual display makes it easy to operate with simple and intuitive parameter adjustments.

- Efficient Cooling System: A strategically designed cooling port helps to prevent the machine from overheating during prolonged use, ensuring consistent performance throughout extended operations.

- Stable Blowpipe Design: The continuous and stable blowpipe ensures that the product remains free of oxidation and blackening during the welding process, maintaining the quality of the workpiece.

APPLICATIONS & MATERIALS

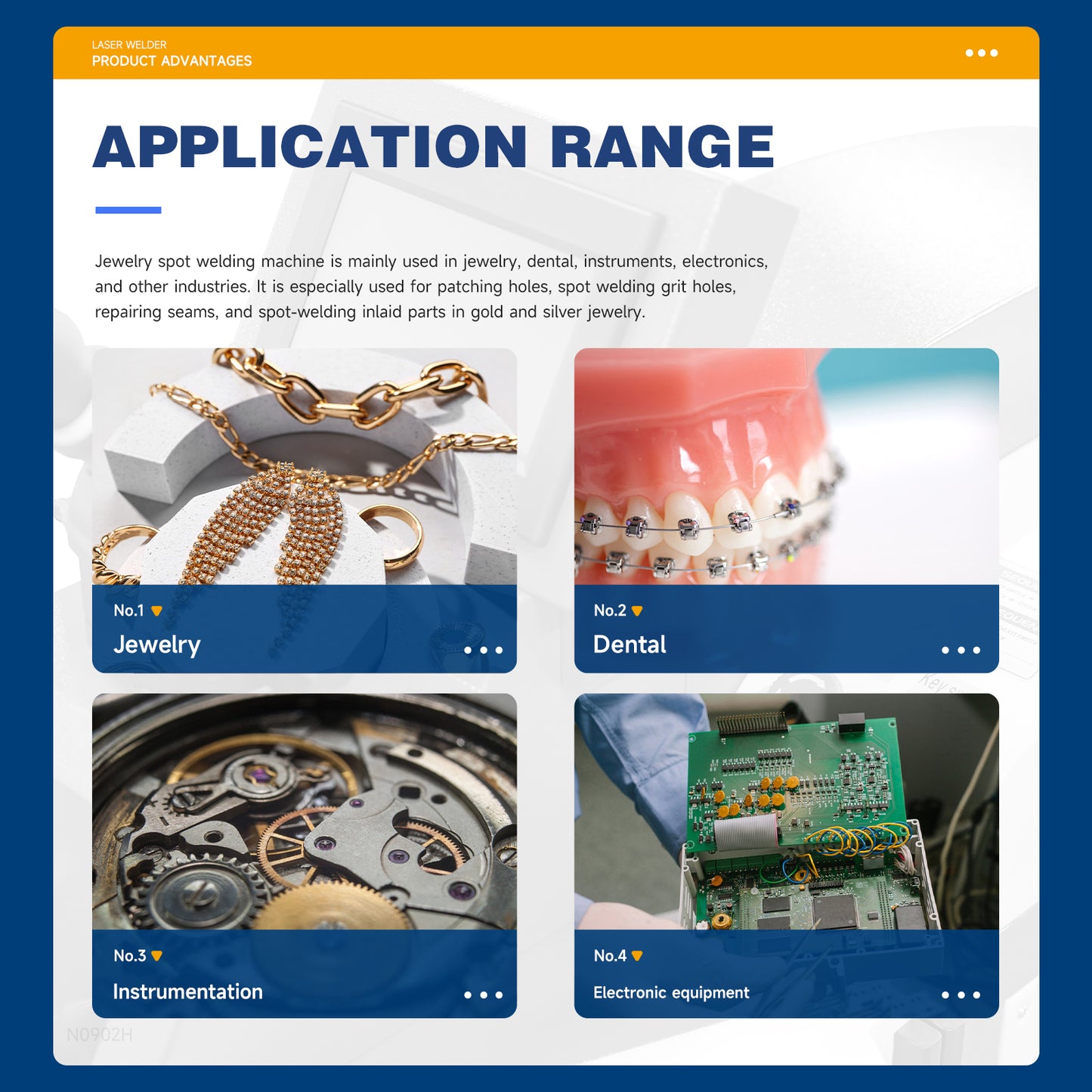

The LJW-200 Jewelry Laser Spot Welding Machine is widely used across various industries, including:

- Aviation & Aerospace

- Jewelry

- Medical Equipment

- Aluminum Alloy Dentures

- Instruments & Electronics

- Machining

- Automobiles

It's particularly effective for repairing gold and silver jewelry, filling holes, welding seams, patterns, inlaid parts, and claw foot parts, providing reliable and precise welding results in these industries.

Share